Centrifuges are used to remove small solids from an active drilling fluid system and recover valuable drilling fluid which is recycled into the drilling fluid system. The process enhances drilling efficiency in oil based and water based drilling fluids and reduces disposal costs and haul-off expenses. Use of a centrifuge can also allow barite to be recovered and recycled to the drilling fluid system if desired.

IFS centrifuges come in a variety of sizes and configurations and can be customized to fit drilling conditions. Our centrifuges are available in both fixed drive and variable drive configurations and have customized hardware and software packages that can be designed to meet specific installation and operation needs. Use of the Variable Frequency Drive (VFD) option allows the centrifuge to be set to respond to varying conditions encountered while drilling.

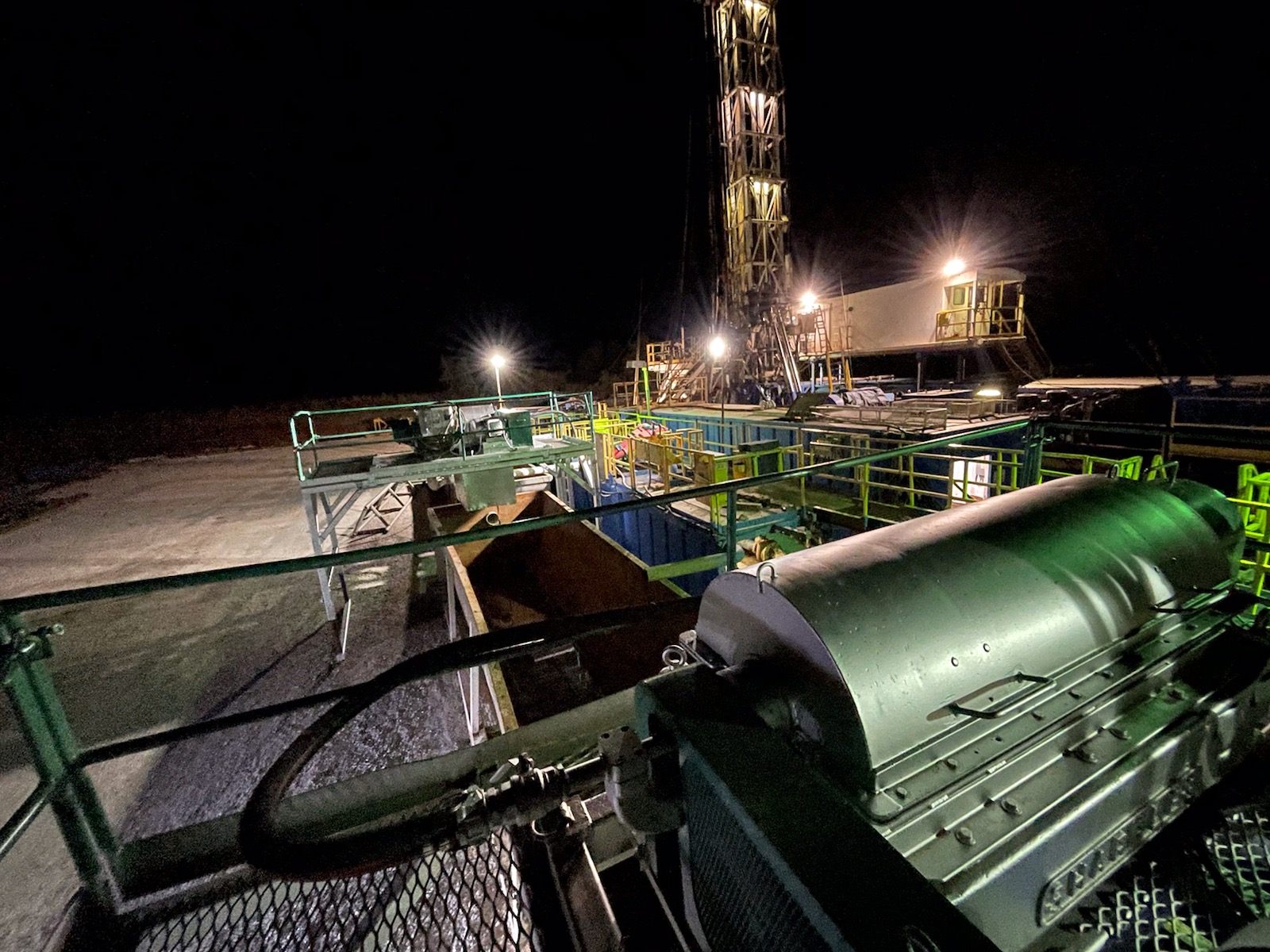

IFS Centrifuges

IFS centrifuges are designed and manufactured to ensure continuous duty and reduce overall drilling costs by:

- Controlling the mud weight

- Removing potentially damaging solids

- Returning clean fluid to the mud system

- Recovering and returning barite to the mud system

Optional VFD Control Panel

IFS 18 x 58 centrifuges are now available with an optional VFD control panel

- True Variable Frequency Drive control provides torque-driven preset adjustability while drilling to maximize operating efficiency and improve solids removal